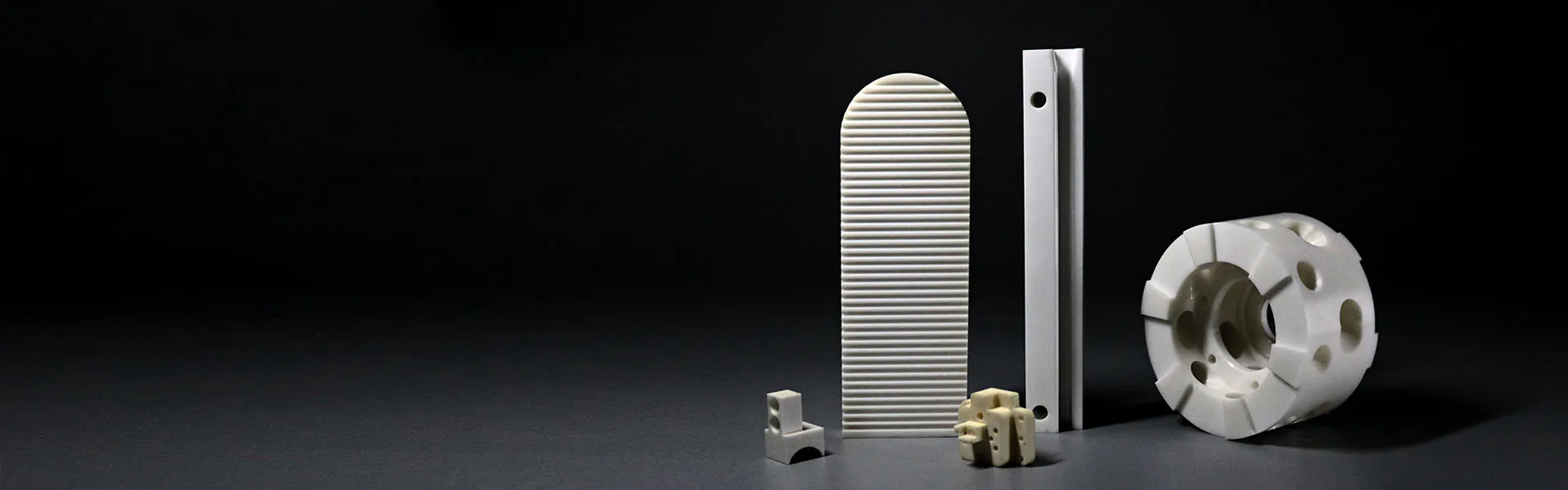

Professional Custom Parts

One-stop Solution from Sample to Mass Production

Precision Manufacturing

Tolerance Control ±0.001mm

Premium Materials

Multiple High-Performance Materials Available

Rapid Response

Sample Delivery Within 72 Hours

Non-disclosure Agreement Available

Advanced Ceramics Series

We deliver end-to-end manufacturing solutions for high-performance advanced ceramics and precision tungsten carbide components, from material selection to finished product delivery. Our state-of-the-art equipment and 20+ years of expertise ensure precision, consistency, and reliability for your most demanding applications.

Alumina Ceramic

A go-to advanced ceramic with high strength, hardness, thermal stability, wear resistance, and electrical insulation. XYC delivers precision alumina ceramic (97%–99.8% Al₂O₃) for critical industrial applications including insulators and high-temperature fixtures.

Key Specifications:

- Hardness: HRA 90–93 (wear-resistant)

- Electrical Resistivity: ≥ 1×10¹⁴ Ω·cm (HV insulation/electronic substrates)

- Strength: Flexural 360–600 MPa; Compressive 2250–2700 N/mm² (heavy-load use)

- Max Temp: 1200°C (high-temp stability)

Typical Applications

- Electrical insulation components

- High-temperature furnace fixtures

- Wear-resistant pump and valve parts

- Semiconductor manufacturing parts

- Medical device components

Zirconia Ceramic

Zirconia ceramic is a high-performance structural ceramic featuring superior toughness, strength, wear resistance and biocompatibility. Stabilized zirconia offers stable dimensions across broad temperatures, suited for precision engineering. XYC supplies precision zirconia components for industrial, medical and high-tech uses.

Key Specifications:

- Toughness: 6–10 MPa·m^(1/2) (chip/fracture-resistant)

- Thermal Conductivity: 3 W/(m·K) (good heat insulation)

- Max Temp: 1000°C (stable in thermal cycles)

- Chemical Stability (acid/alkali/solvent-resistant)

- Thermal Expansion: ≈10×10⁻⁶/K (steel-compatible)

Typical Applications

- Medical implants and surgical instruments

- Precision cutting tools and wear-resistant parts

- High-temperature sensor components

- Insulation sleeves for thermal management

- Valve and pump components in corrosive environments

Silicon Nitride Ceramic (Si₃N₄)

Silicon nitride ceramic is a high-performance structural ceramic ideal for harsh environments, featuring high strength, hardness, and resistance to heat, oxidation and corrosion. Its balanced electrical insulation and thermal conductivity make it perfect for critical applications.

Key Specifications:

- Hardness: 92.5 HRA (wear-resistant)

- Bending Strength: 850 MPa (high-stress load-bearing)

- Density: 3.20 g/cm³ (high strength-to-weight ratio)

- Fracture Toughness: 6.0–7.0 MPa·m^(1/2)

- Max Temp: 1400°C (extreme heat compatible)

Typical Applications

- High-temperature bearing components

- Gas turbine engine parts

- Precision cutting tools for hard materials

- Corrosion-resistant pump and valve components

- Aerospace structural components

Silicon Carbide Ceramic (SiC)

Ultra-hard, diamond-like SiC is a lightweight advanced ceramic with excellent thermal conductivity, low thermal expansion, and strong acid/alkali/thermal shock resistance—crack-free in rapid temperature cycles.

Key Specifications:

- Density: 3.20 g/cm³ (high strength-to-weight ratio)

- Hardness: 94 HRA (superior wear resistance)

- Thermal Conductivity: 80 W/(m·K) (efficient heat dissipation)

- Thermal Expansion: 4.5×10⁻⁶/K (thermal cycling stability)

- Max Temp: 1600°C (extreme heat compatible)

Typical Applications

- Kiln furniture and furnace linings

- High-temperature heat exchangers

- Wear-resistant pump and valve components

- Semiconductor manufacturing equipment parts

- Thermal management substrates for high-power electronics

Magnesium Zirconium Ceramics

MgO-stabilized zirconium ceramic with high fracture toughness, thermal shock resistance, and high-temperature stability. Ideal for harsh, high-stress industrial applications.

Key Features:

- High fracture toughness (anti-cracking/failure)

- Superior thermal shock resistance (rapid temp changes)

- High-temperature stability (strength retention)

- Corrosion & wear resistance (harsh environments)

- Long-term anti-aging performance

Typical Applications

- High-temperature furnace fixtures and kiln furniture

- Thermal processing equipment components

- Cutting tools for high-speed machining

- Wear-resistant pump and valve parts in extreme environments

- Aerospace and automotive components

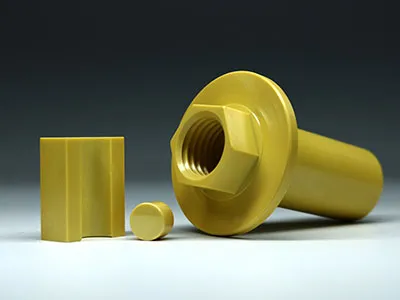

Tungsten Carbide Custom Parts

A high-performance composite of tungsten carbide and metallic binders (e.g. cobalt), delivering extreme hardness, exceptional wear resistance, and high compressive strength.

Key Features:

- Extreme hardness (HRA 86–93) for superior wear resistance

- High compressive strength for heavy-load stability

- Precision machinability for complex geometries

- Dimensional stability under prolonged use

- Corrosion resistance in harsh industrial fluids

Typical Applications

- Metalworking cutting tools & inserts

- High-wear injection molding & stamping molds

- Mining & drilling tools

- Aerospace & automotive precision components

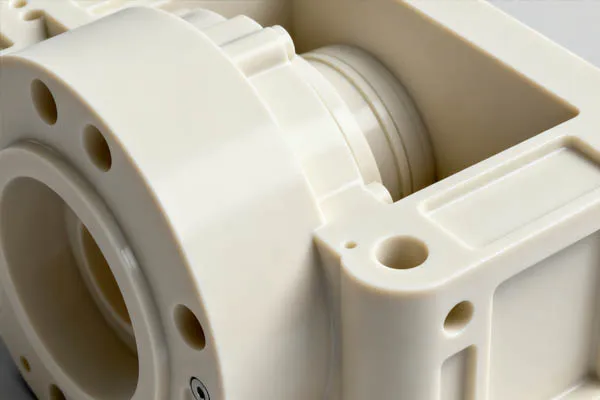

Core Processing Capabilities

Focused on high-precision advanced ceramic manufacturing, providing full-process industrial ceramic solutions from material selection to finished product delivery

Providing Complete Advanced Ceramic Technology Solutions

Equipped with precision processing capabilities for various ceramic materials such as alumina, zirconia, and silicon nitride, with processing accuracy up to ±0.001mm and surface roughness Ra≤0.02μm.

- Materials Covered: Alumina (Al₂O₃), Zirconia (ZrO₂), Silicon Carbide (SiC), Silicon Nitride (Si₃N₄)

- Full-Process Control: Formula development → Forming → Sintering → Precision machining → Surface treatment → Quality testing

- Precision Up to ±0.002mm tolerance, sub-nanometer form accuracy

- Key Equipment: Pressure sintering furnace, 5-axis CNC machining centers, Zeiss 3D coordinate measuring machine

- Target Industries: Laser semiconductors, new energy vehicles, aerospace, petrochemicals

Precision Tungsten Carbide Processing

Specialized in processing various grades of Tungsten Carbide materials, equipped with high-end equipment such as 5-axis machining centers, capable of processing complex-shaped Tungsten Carbide parts with hardness up to HRC90+.

- Materials Covered: Various grades of tungsten carbide (WC) materials

- Processing Capabilities: 5-axis CNC machining, precision grinding, EDM, and complex geometry forming

- Precision: Up to ±0.002mm tolerance for critical components

- Key Equipment: 5-axis CNC machining centers, optical curve grinding machines, mirror EDM machines

- Target Industries: Precision Equipment, Petrochemicals, Automotive New Energy, and Precision Fluid Control.

Advanced Ceramic Component Customization

Capable of producing metal and industrial ceramic components, with an annual output of over 5 million precision components, serving 500+ global customers.

- Customization Scope: Prototyping, small-batch production, and high-volume manufacturing

- Rapid Turnaround: 10-15day delivery for custom prototypes

- Material & Process Flexibility: Tailored solutions for specific performance requirements (wear resistance, insulation, thermal conductivity)

- Annual Capacity: 800,000+ precision components annually

- Target Industries: All high-end sectors, supporting fast iteration for new energy and semiconductor clients

Precision Finishing Services

High-accuracy plane, internal/external cylindrical, and profile grinding (±0.001 mm accuracy) with imported precision grinders. Mirror-finish grinding meets optical, semiconductor, and aerospace surface quality requirements.

CNC Turning Services

High-precision CNC lathes with automatic feeding systems for efficient mass production of rotating components (shafts, discs, precision fittings). Delivers consistent dimensional accuracy for automotive, aerospace, and industrial equipment sectors.

Advanced Ceramic Machining

Precision machining of high-hardness, high-brittleness ceramics (alumina, zirconia, silicon nitride, silicon carbide). Services include surface grinding, cylindrical grinding, CNC milling, and laser cutting (±0.001 mm accuracy). Ideal for medical, semiconductor, and high-temperature industrial components.

Assembly & Testing Solutions

Comprehensive assembly and performance testing for ceramic components. Professional equipment ensures products meet functional and quality requirements, reducing supply chain complexity and accelerating time-to-market.

About XYC | Custom Advanced Ceramics Manufacturer

4

Production Bases

20+

Industry Experience (Years)

30+

R&D Team Members

300+

Employees

1000+

Served Customers

28500

Production Workshop (㎡)

Visit XYC Ceramics

Watch our corporate video → See our tech, our factories, our expertise in action

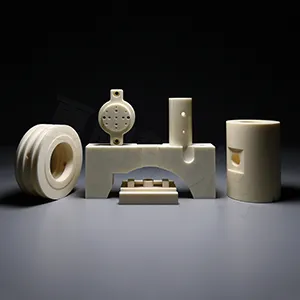

Product Center

We provide a variety of high-performance ceramic materials and products to meet the special needs of different industries

Custom Ceramic Solutions

Tailored ceramic components engineered to your exact specifications, solving unique industrial challenges.

Ceramic Pump and Valve Plunger

Made of toughened structural ceramic materials, high mechanical strength, long service life With wear resistance, corrosion resistance, high temperature stability,chemical...

Welding Roller

*Material has high hardness, high temperature resistance, and excellent thermal shock stability *High bending and compressive strength *Surface profile accuracy...

Ceramic Roller-ceramic Dual-roll-ceramic Three-roll

*Material has high hardness, high wear resistance, non-magnetic and non-conductive. *Exceptional thermal stability and maintains its performance even underhigh-temperature working...

Silicon Nitride Ceramic Substrate | 6-inch CNC Machined Precision Component | Semiconductor Industry

This 6-inch silicon nitride ceramic substrate is a precision CNC-machined component engineered for semiconductor manufacturing equipment and high-precision industrial systems....

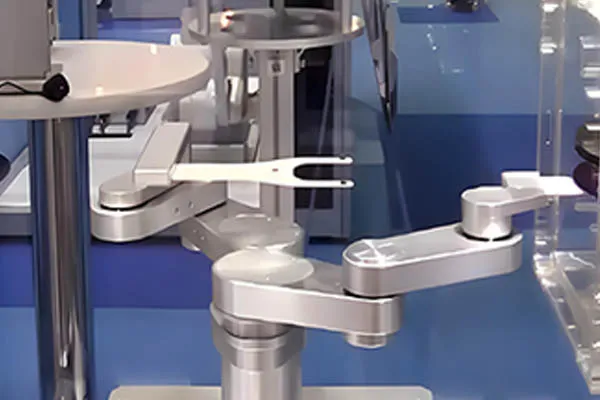

Ceramic mechanical arm / Semiconductor wafer equipment / Handling arm

Ceramic mechanical arm / Semiconductor wafer equipment / Handling arm Excellent wear resistance, high temperature resistance, corrosion resistance, thermal shock...

Precision Ceramic Parts

Can do special shaped fine processing, range can be up to 250mm X 200mm X 200mm The precision can reach...

Tungsten Carbide Parts

Tung.sten carbide has excellent properties such as abrasion resistance, corrosion resistance and hiehtemperature resistance, and is increasingly used in various...

Our Manufacturing Capabilities

Advanced production equipment and processes ensure the provision of high-quality ceramic products to customers

Our Manufacturing Capabilities

Advanced production equipment and processes ensure the delivery of high-quality, precision ceramic products to customers worldwide.

Advanced Production Processes

XYC operates a complete, state-of-the-art ceramic production line, from raw material preparation to finished product machining. Every stage is rigorously controlled to guarantee consistent, reliable quality that meets the most demanding industry standards.

Raw Material Preparation

We source high-purity raw materials and employ precise proportioning, achieving sub-micron particle size control to ensure uniform material performance and a solid foundation for superior ceramics.

Forming Technology

Our versatile forming capabilities include dry pressing, isostatic pressing, and injection molding, enabling the production of complex-shaped components that meet diverse design requirements.

Sintering Process

Using imported atmosphere sintering furnaces with ±1°C temperature control precision, we achieve high-temperature sintering up to 1800°C, ensuring optimal material density and mechanical properties.

Precision Machining

Leveraging diamond grinding wheels and laser processing technology, we achieve machining precision of ±0.001 mm, delivering components that meet the most stringent high-precision application demands.

Strict Quality Control

Raw Material Inspection

Each batch of raw materials undergoes rigorous inspection to verify purity, particle size, and other critical parameters. By controlling quality at the source, we lay the foundation for consistent, high-performance ceramic components.

Process Control

Key production parameters are monitored in real time, with strict quality checks at every stage. This proactive approach ensures production stability and minimizes variability, guaranteeing uniform quality across all products.

Finished Product Testing

Comprehensive testing is performed on all finished products, including dimensional accuracy, density, hardness, and mechanical strength. Every component must meet or exceed customer specifications before delivery, ensuring complete satisfaction.

Application Areas

XYC Ceramics delivers advanced ceramic solutions that power innovation across key industrial sectors worldwide.

Electronics & Semiconductors

Our high-performance ceramic substrates, insulators, and packaging materials meet the stringent requirements of the electronics and semiconductor industries, providing exceptional high-temperature resistance, electrical insulation, and thermal conductivity to ensure the reliability of cutting-edge electronic devices.

Learn More Semiconductor industry

Medical Devices

As a trusted supplier to the medical industry, we offer biocompatible ceramic materials for a wide range of applications, including surgical instruments, artificial joints, and dental implants. Our ceramics are engineered for safety, reliability, and long-term performance in critical healthcare environments.

Learn More Food and medical industry

Automotive Industry

Our precision ceramic bearings, sensors, and wear-resistant components are designed to enhance the efficiency and reliability of new energy vehicles and advanced automotive systems. With superior heat resistance and durability, they play a vital role in the next generation of automotive technology.

Learn More Automotive Industry

Precision Machinery

Our high-precision ceramic structural components, guide rails, and bearings deliver exceptional wear resistance and dimensional stability, ensuring the long-term reliability of precision machinery in demanding industrial environments.

Learn More Precision machinery industry

New Energy

Our ceramic insulation materials and wear-resistant components are critical to the performance of photovoltaic, wind power, and energy storage systems. Engineered for high temperatures and extreme durability, they help improve the efficiency and reliability of new energy equipment.

Learn More New energy vehicle industry

Tungsten Carbide Custom Parts

Our high-performance tungsten carbide components are engineered for exceptional hardness and wear resistance, making them ideal for precision mechanical parts and high-strength structural components. They ensure stable operation of equipment under extreme conditions, from aerospace to heavy industry.

Learn MoreCustomer Cases

We partner with leading global enterprises across industries to deliver high-quality ceramic material solutions that drive performance and reliability.

Semiconductor Equipment Ceramic Component Solutions

We supplied high-precision alumina ceramic components to a top semiconductor equipment manufacturer, significantly extending the equipment's service life and improving operational stability in high-throughput production environments.

View Details

Medical Equipment Zirconia Ceramic Components

We developed biocompatible zirconia ceramic components for a leading medical device enterprise, meeting strict medical-grade material requirements. These components are now widely used in surgical instruments and diagnostic equipment, ensuring safety and reliability for patients.

View Details

New Energy Vehicle Motor Ceramic Bearings

Provided high-performance silicon nitride ceramic bearings for new energy vehicle manufacturers, improving motor efficiency, reducing energy consumption, and extending service life.

View DetailsCustomer Reviews

Genuine feedback from industry leaders about our products and services

"The alumina ceramic components from XYC have consistently delivered stable quality and exceptional dimensional accuracy. This has directly boosted our production efficiency by 20%. Their technical support team is highly professional and always responds to our needs quickly—they’re a reliable partner we can count on."

Director Zhang

Electronic Equipment Manufacturer

"As a medical device enterprise, we have extremely strict requirements for materials. XYC's zirconia ceramic products not only meet our rigorous quality standards but also offer excellent biocompatibility and high processing precision. They’ve become our trusted supplier for critical components."

Manager Li

Medical Device Company

"We integrated XYC's silicon nitride ceramic bearings into our new energy vehicle motors, and the results have been outstanding. Motor efficiency has improved, and failure rates have dropped significantly. Their customization service is also top-notch—they quickly provide tailored solutions that meet our exact specifications."

Engineer Wang

Automotive Manufacturing Enterprise

Contact Us

No matter what questions or needs you have, our professional team will provide you with timely and professional services

Send an Inquiry

Contact Us

Need Custom Advanced Ceramic Products?

Partner with XYC Ceramics for precision-engineered solutions Our professional R&D team and state-of-the-art production facilities enable us to customize high-performance ceramic components tailored to your exact specifications.