Customer Cases

We offer a full range of high-performance ceramic materials and customized machined parts to meet the special requirements of different industries for hardness, wear resistance, high temperature resistance, and other special requirements.

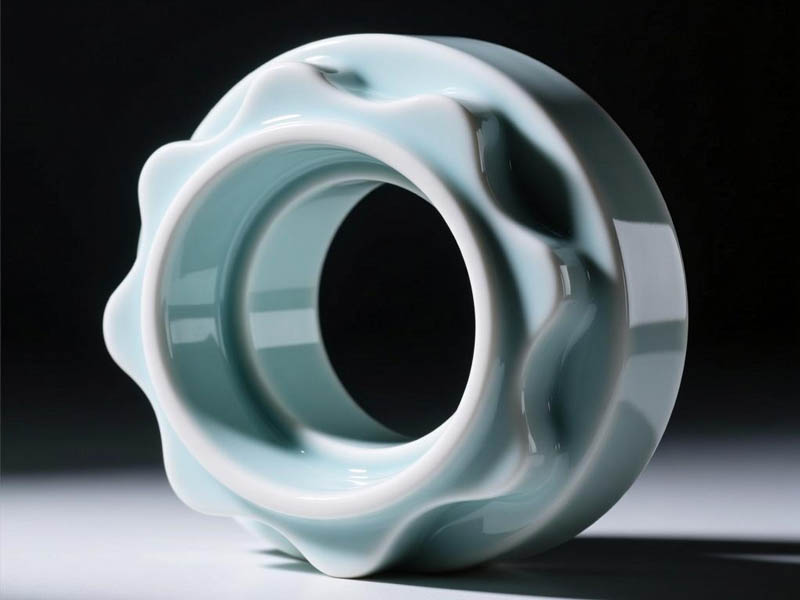

Ceramic robot arm for semiconductor equipment

Ceramic robot arm, also known as ceramic mechanical fingers, wafer tray, wafer robot arm, etc., mainly in the semiconductor equipment to play the role of transportation and handling, which is equivalent to the semiconductor equipment, the robot's hand, responsible for handling wafers and silicon wafers to the designated location.

Case overview

Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Success Cases Cases Successful Cases Successful Cases Successful Cases Successful Cases Successful Cases Successful Cases

Product Features

1. High product precision

2. Good air tightness

3. Good resistance to high temperature

4. Controllable surface resistivity

5. Acid and alkali resistance, strong corrosion resistance, can adapt to the extremely poor

▲Self-containment test: shut down the air source, negative pressure -85Kpa to -80Kpa, the length of time up to more than 60s

▲Wafer adsorption detection: shut down the real air source, negative pressure -80Kpa to -25Kpa, the length of time up to more than 35s

| Product Performance | unit (of measure) | parameters | |

| resistivity | Ω | silicon carbide | 1×105 |

| aluminum oxide | 1×1014 | ||

| Maximum operating temperature | ℃ | Split arm | 350 |

| One-piece arm | 800 | ||

| Adsorption surface finish | Ra | 0.01 | |

| Adsorption surface flatness | m m | Within 0.01 | |